EASA FORM-1

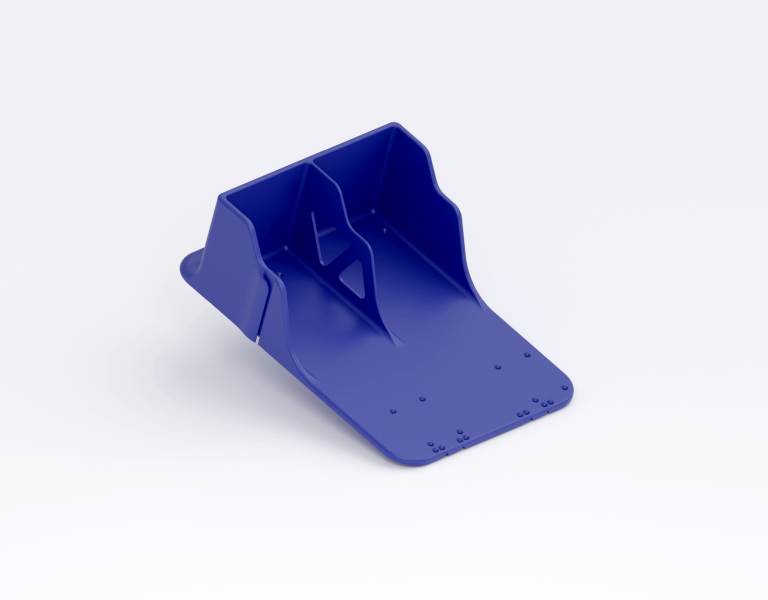

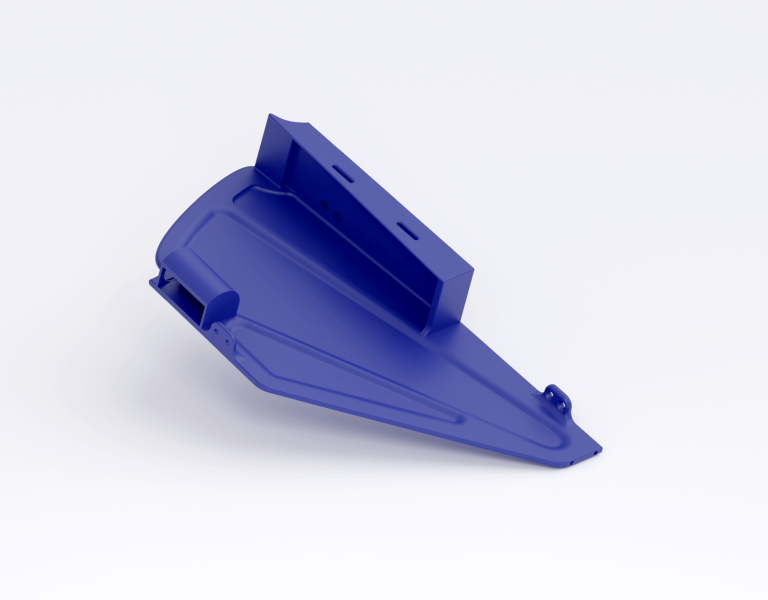

Business Economy seat components

First Class, Business, and Business Economy seat manufacturing can be optimized in two ways – through part consolidation, and by replacing metal components with printed plastic ones. Customized printed designs are efficient when it comes to manufacturing thanks to the reduction in the number of parts, as well as the highly customizable design, which allows for any changes to be made quickly. Further cost reduction can be gained via increased manufacturing ergonomics and reduction of DO-related admin.

Sub-assemblies of B/C Seats are commonly unnecessarily complex due to limitations of the used materials and production technologies that suit the low-volume production. Additional customizability expected by the airlines may necessitate further compromises in the product design.

On-demand manufacturing -

MOQ of 1

Reduced lead time

- down to hours

Reduced weight

and parts count

Easy customization

– minimal additional costs

0 waste manufacturing -

no leftovers

Solutions

Challenge

Seat center consoles can have upward of 200 individual parts, which hinders design and assembly processes

Solution

Traditionally complex assemblies printed as a single part eliminates large number of manufacturing as assembly steps

Challenge

Multi-part components are prone to supply chain disruptions and procurement errors

Solution

Printed designs are resilient and independent of supply chain disruptions as they can be manufatrued on site, on demand

Technical details

Printing time per unit: up to 42h

Weight: Reduced at least 10% compared to traditional manufacturing

Lead time/unit: 5-7 days

Certification: EASA Form 1

Materials: Ultem 9085 Certified Grade

Surface finish: Specified by customer

Backup your parts with EMEA's largest small-batch manufacturer

Minimum order quantity: 1

60+ FDM printers in manufacturing network

Multiple locations offer next-door service

Short turnarounds – down to hours