EASA FORM-1

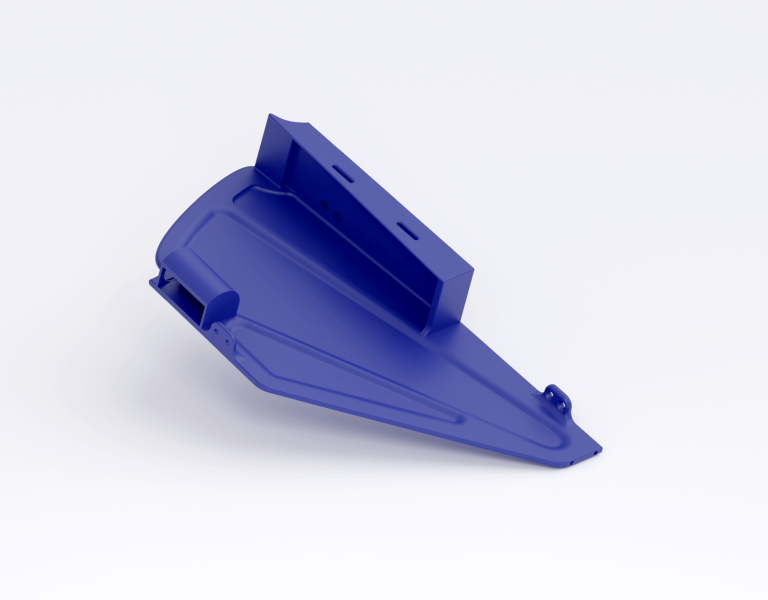

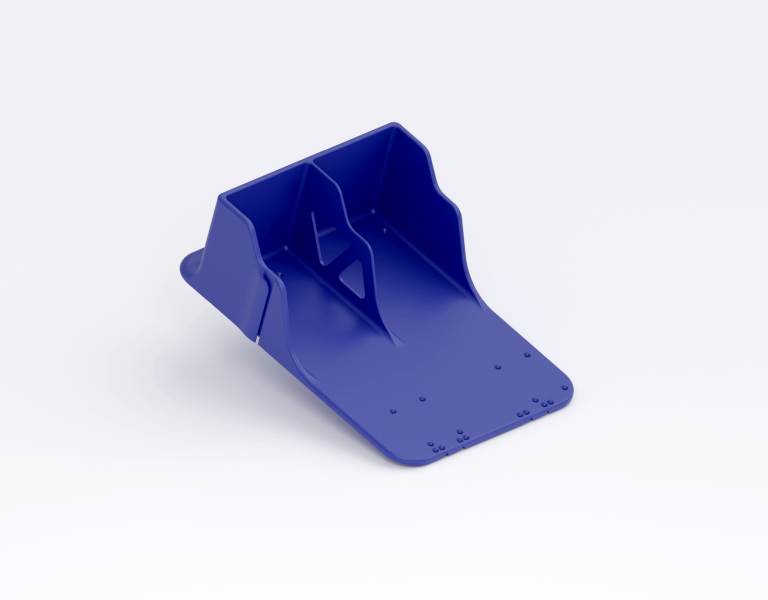

Seat armcap

Lifespan and operational feasibility of a passenger seat is highly depends on the availability of spares. Seat armcaps, being one of the hard surfaces that are the most interacted with, are a common headache for procurement teams. Additive manufacturing can replace the traditionally produced units, either as full plastic parts, or in combination with materials such as leather and fabric.

On-demand manufacturing -

MOQ of 1

Reduced lead time

- down to hours

Reduced weight

and parts count

Easy customization

– minimal additional costs

0 waste manufacturing -

no leftovers

Solutions

Challenge

Seat armcaps are among the most commonly worn out components

Solution

Additive manufacturing makes any design of seat armcaps quickly available when worn out

Challange

OEM armcaps may not be available anymore or with reasonable lead time

Solution

Designs that are no longer manufactured can be easily reverse-engineered to ensure a longer lifecyle for seats

Challenge

Reproducing armcaps in traditional ways is not financially feasible in low volumes

Solution

On-demand manufacturing makes it cost-effective to manufacture components on-demand in small quantities

Challenge

Replacement parts are not always available in the required finishes

Solution

Armcaps can be either color-matched to blend in with the original parts or completely re-designed and upholstered with materials such as leathers and vinyls

Technical details

Printing time per unit: 3.6h

Weight: Reduced by 17% compared to original PU-foam overmolded part

Lead time/unit: 100 units every 10 days

Certification: EASA Form 1

Materials: Ultem 9085 Certified Grade

Additional components: Thread inserts for mounting

Backup your parts with EMEA's largest small-batch manufacturer

Minimum order quantity: 1

60+ FDM printers in manufacturing network

Multiple locations offer next-door service

Short turnarounds – down to hours