EASA FORM-1

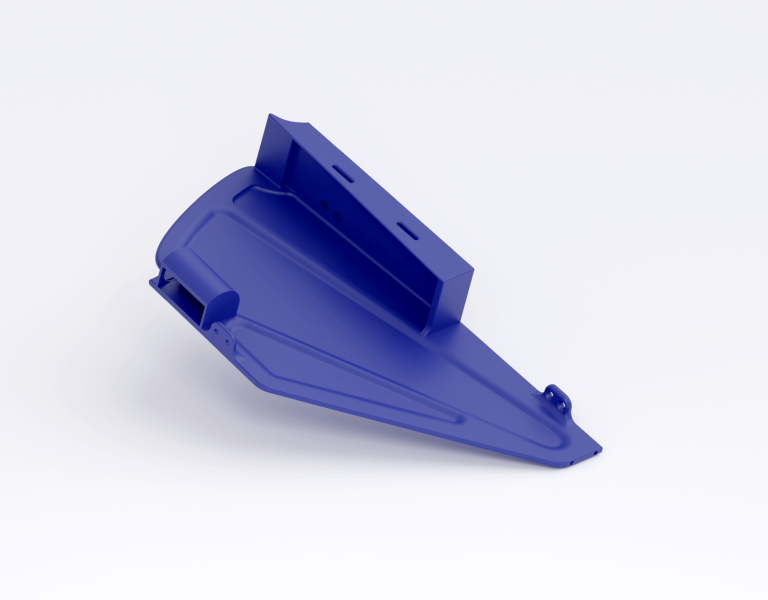

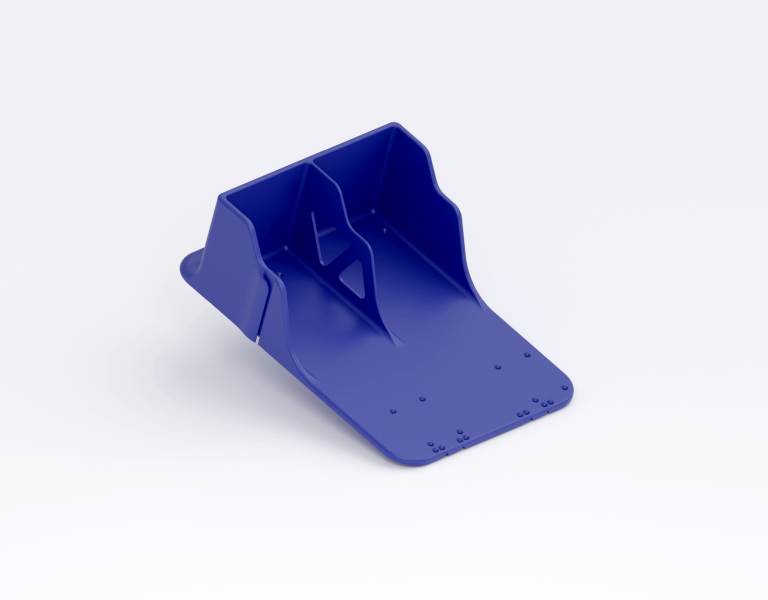

Custom seat panels with In-Seat power provisions

Third-party in-seat power solutions can often not be installed in locations which are easily reachable in high seat-density configurations. Printed facia panels for the power outlets allow for improved user experience and are feasible even for customers with a single aircraft installation.

On-demand manufacturing -

MOQ of 1

Reduced lead time

- down to hours

Reduced weight

and parts count

Easy customization

– minimal additional costs

0 waste manufacturing -

no leftovers

Solutions

Challenge

Traditional aftermarket in-seat power solutions attach to the downtubes and are thus too low to comfortably use

Solution

Exact position and cable routing can be fined tuned to allow the best mix of ergonomics, durability and ease of installation

Challenge

Available replacement components rarely match exact interior design requirements

Solution

Printed outlet panels can be easily matched with the rest of the seat design

Technical details

Printing time per unit: 4.6h

Lead time/unit: 5 days

Certification: EASA Form 1

Materials: Ultem 9085 Certified Grade

Surface finish: ALEXIT painting system

Backup your parts with EMEA's largest small-batch manufacturer

Minimum order quantity: 1

60+ FDM printers in manufacturing network

Multiple locations offer next-door service

Short turnarounds – down to hours