EASA FORM-1

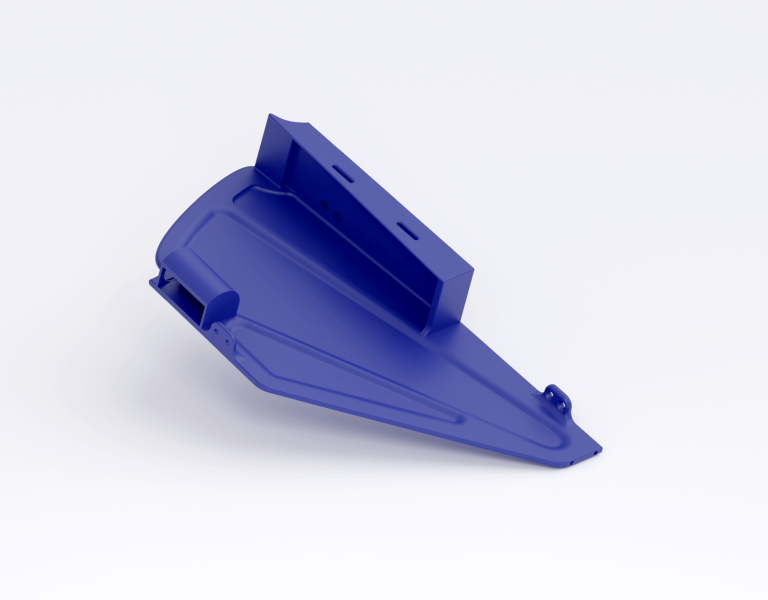

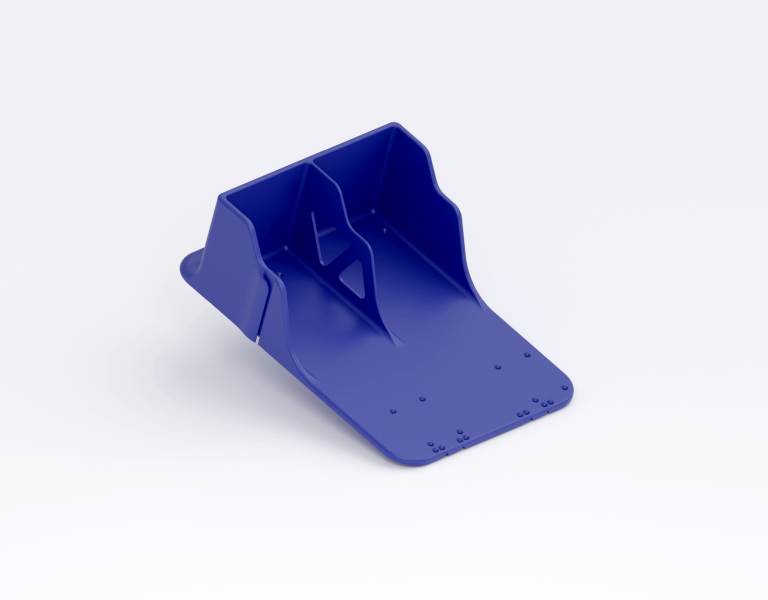

Tools for composite and sheet metal forming

Fabricating specialized tools for small-batch manufacturing could easily ruin the feasibility or schedule of a project. Complex geometries of molds, forming tools, specialized drilling jigs can be printed in one go, reducing the required lead times of the finished products.

On-demand manufacturing -

MOQ of 1

Reduced lead time

- down to hours

Reduced weight

and parts count

Easy customization

– minimal additional costs

0 waste manufacturing -

no leftovers

Solutions

Challenge

Custom, high-complexity tools are not always feasible for small batch production

Solution

3D-printed tools are an economical alternative to tools traditionally made from materials such as stainless steel

Challenge

Creating custom tools takes time and can increase lead time to start manufacturing components

Solution

Tools can be printed on-site where needed and when needed and adjusted quickly as needed

Challenge

Missing specialized tools such as drilling jigs can leads to higher rates of user error

Solution

Tools with guide holes can be quickly manufactured for price drilling operations

Technical details

Tool working temperature: up to 180 Celsius

Lead time/unit: 3-7 days

Materials: Ultem 9085 or Ultem 1010

Surface finish: Raw, sanded, polished

Backup your parts with EMEA's largest small-batch manufacturer

Minimum order quantity: 1

60+ FDM printers in manufacturing network

Multiple locations offer next-door service

Short turnarounds – down to hours