EASA FORM-1

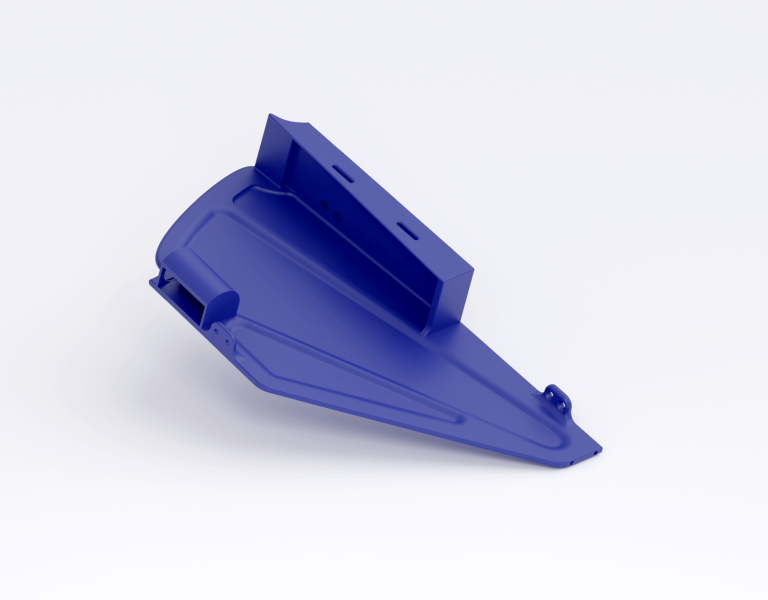

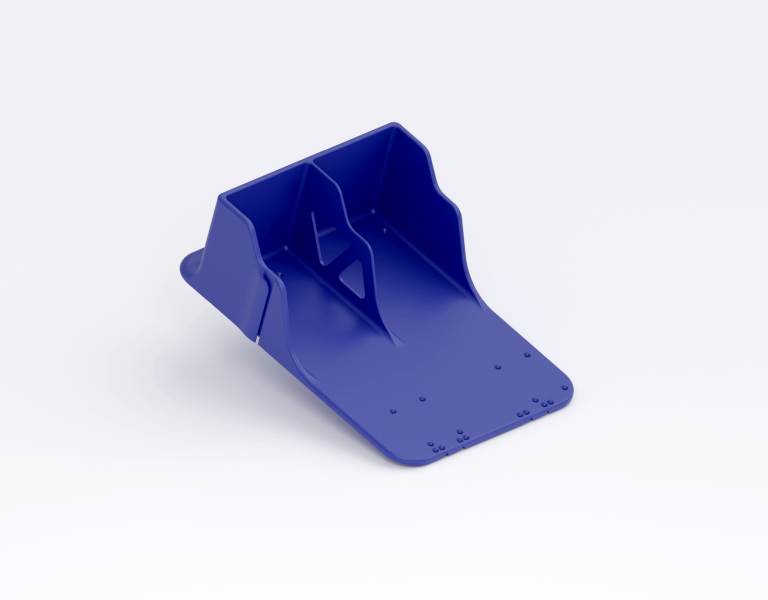

Seat backrest reinforcements

Modern, thin, and lightweight seat panels can be prone to premature failure due to daily wear and tear, exposure to high/low temperatures, and unforeseen forces. Internally-mounted brackets, supports, and doublers can be easily optimized and printed to strengthen seat panels and eliminate common points of failure.

On-demand manufacturing -

MOQ of 1

Reduced lead time

- down to hours

Reduced weight

and parts count

Easy customization

– minimal additional costs

0 waste manufacturing -

no leftovers

Solutions

Challenge

Making highly complex geometry parts traditionally is not feasible

Solution

Printed repair brackets are designed to reinforce weak spots in original panels

Challenge

Replacing the whole panel may not be feasible due to cost, availability and lead time

Solution

Reinforcements are designed in a way which allows mechanics to easily bond them in place without special training or equipment

Challenge

Repairing thin panels using composites is reactive solution that is time consuming and can still stay visible as a repair

Solution

Printed doublers can take the point loads and spread them across larger areas which reduces loads on the main panel

Technical details

Printing time per set: 0.5 hours

Lead time/unit: 300 sets every 20 days

Certification: EASA Form 1

Materials: Ultem 9085 Certified Grade

Backup your parts with EMEA's largest small-batch manufacturer

Minimum order quantity: 1

60+ FDM printers in manufacturing network

Multiple locations offer next-door service

Short turnarounds – down to hours