EASA FORM-1

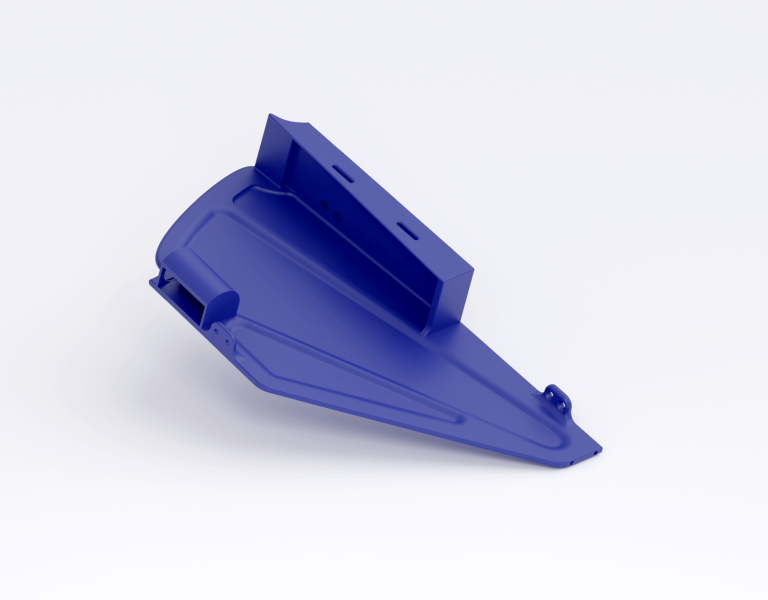

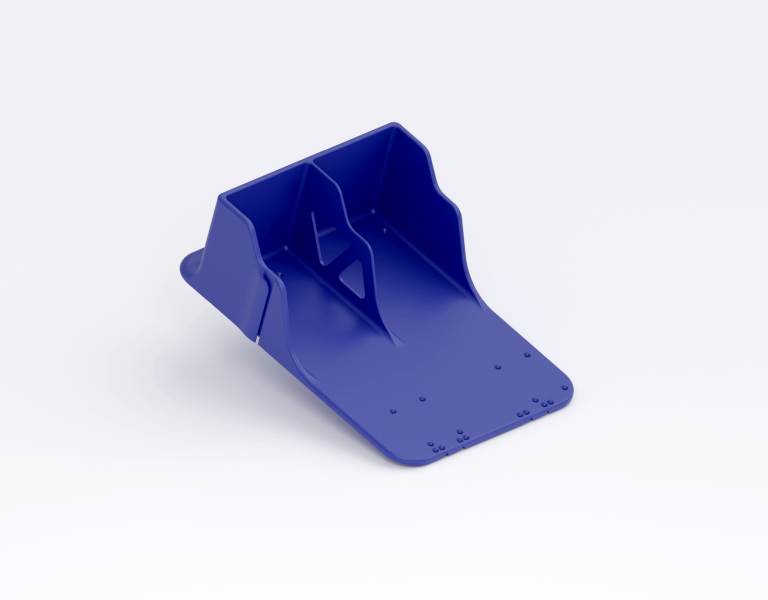

Overhead Bin Divider panel

Emergency Equipment Layout or IFE system may need custom provisions for updated equipment.

Holders, clamps and supports for any equipment in the bin are comonly custom made for a single aircraft.

Every aircraft will face at least 3-5 EEL changes during its lifecycle.

On-demand manufacturing -

MOQ of 1

Reduced lead time

- down to hours

Reduced weight

and parts count

Easy customization

– minimal additional costs

0 waste manufacturing -

no leftovers

Solutions

Challange

Several raw materials, including honeycomb used to produce the assembly

Solution

Redesign to be producible with a single material suitable for Additive Manufacturing

Challange

3 interfacing subassemblies, including brackets, power outlets and IFE server provisions

Solution

Sub-assemblies integrated in a single CAD design produced simultaneously

Challange

Original BOM consisting of 17 components and 9 unique part numbers

Solution

BOM reduction to 3 components and 2 part numbers

Challange

Requires high level of stiffness and structural integrity

Solution

Integrated strengthening rods

Challange

Assembly needs to accommodate several IFE server types; requires updating X number of PNs, drawings, CAD files

Solution

Reconfiguration for new / additional server types requires updating just 2 PNs, drawings, CAD files

Challange

Needs future-proofing for additional emergency equipment provisions

Solution

Easily incorporated with compliance demonstration for such future changes

Technical details

Printing time per unit: 31h

Weight: 1.7kg

Lead time/unit: 3-5 days

Certification: EASA Form 1

Materials: Ultem 9085 Certified Grade

Backup your parts with EMEA's largest small-batch manufacturer

Minimum order quantity: 1

60+ FDM printers in manufacturing network

Multiple locations offer next-door service

Short turnarounds – down to hours